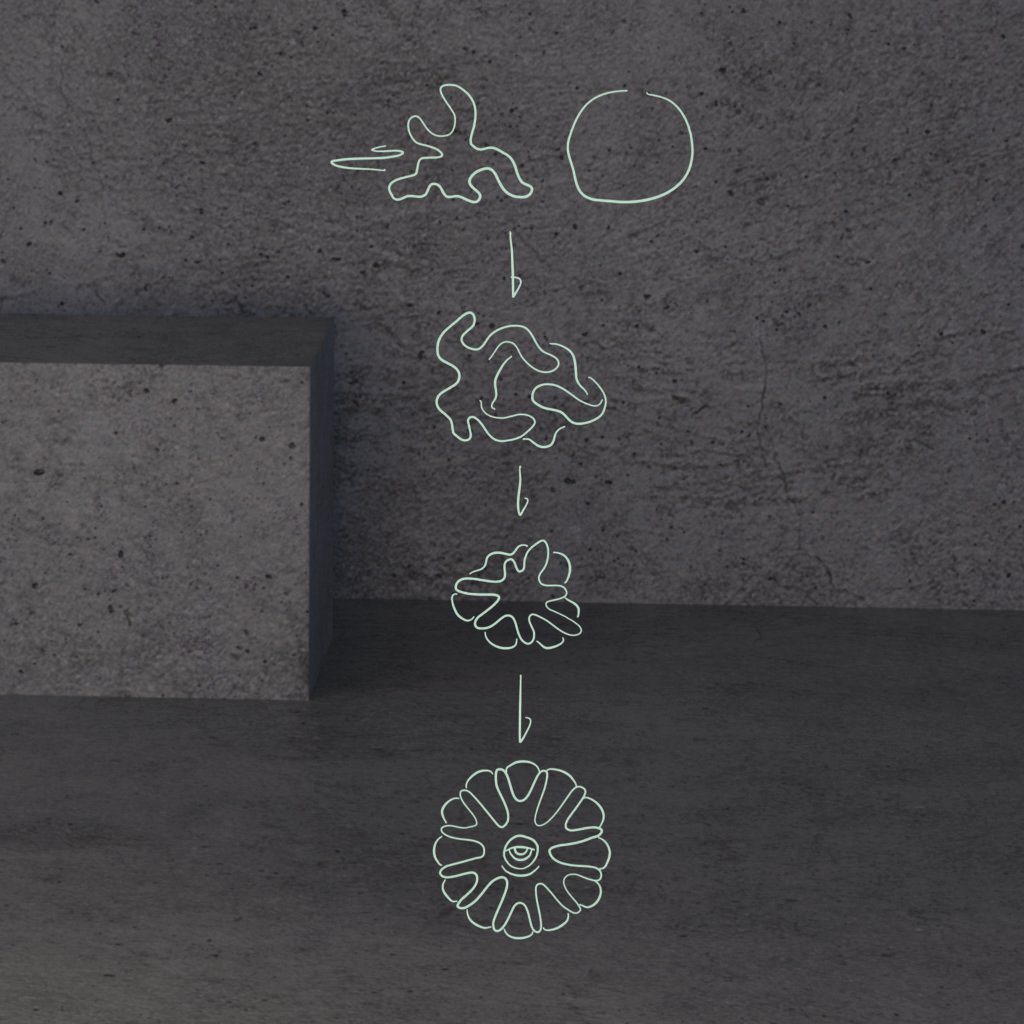

The aim of this project was to gain an introduction to 3D modeling and additive manufacturing. We had the freedom to choose our 3D modeling software. Our teacher provided an off-road scooter with mass-produced wheels. Our task was to design a completely new tire while ensuring it would fit within the scooter’s frame.

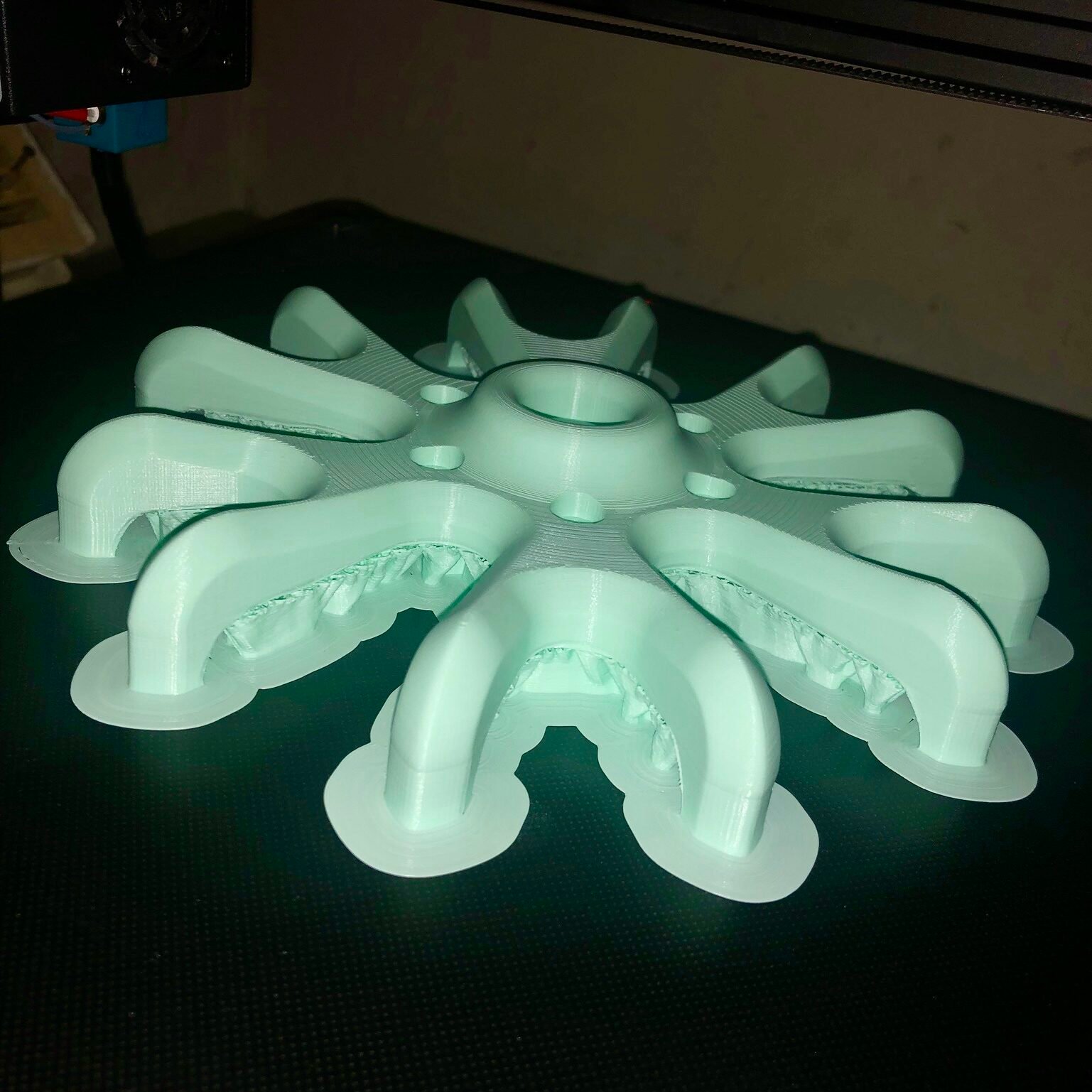

Printing a part of approximately 200mm took more time than I initially anticipated. With multiple test prints, I ended up with around 8 days of printing. Printing the TPU material proved to be much more challenging due to issues such as stringing, warping, and layer separation. For displaying a prototype, a tire made from PLA would be much cleaner in appearance but less bouncy.

Scooters have gained immense popularity in recent years as a convenient and eco-friendly mode of urban transportation. They are commonly used for short-distance commutes, providing a cost-effective and time-efficient means of getting around crowded city streets. However, the scooter I designed might feel more at home on another planet.

| datasheet | |

| timeframe | dez. 2022 – feb. 2023 |

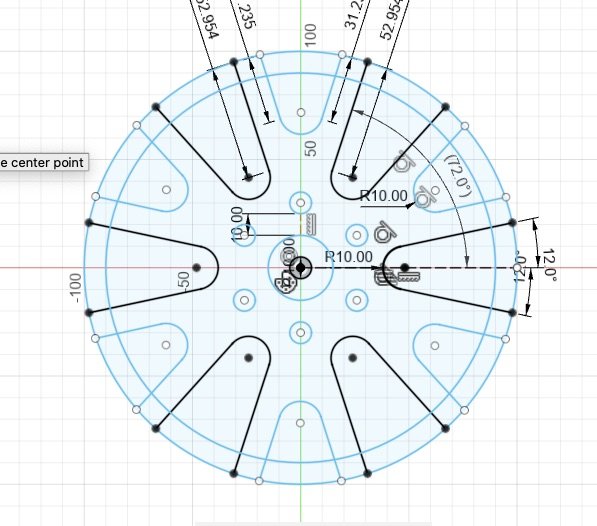

| project category | CAD – technical design |

| mentor | Prof. Jan Vietze |

| project partners | – |

| materials | PLA, TPU, 6x threaded inserts (M6), 12x M6 screws |

| colors (hexadezimal) | #B9E0C8, #4B4948 |

| manufacturing process | FDM print |

| supplier | – |

| download files | Scooter-with-Tires.step |

Leave a Reply